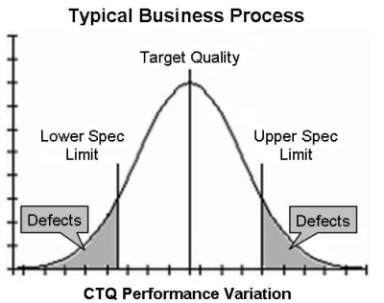

According to the dictionary, a problem is defined as a “question or difficulty needing a solution.” It can also be described as a “deviation from a norm or standard, or a gap between an existing and a desired state.”

My two-word definition for ‘business’ is “problem solving.” We spend our days trying to resolve customer problems, employee problems, marketing problems, financial problems, and operational problems—continually trying to create happy customers, greater profit, and a smooth-running organization.

Systems Thinking to the Rescue

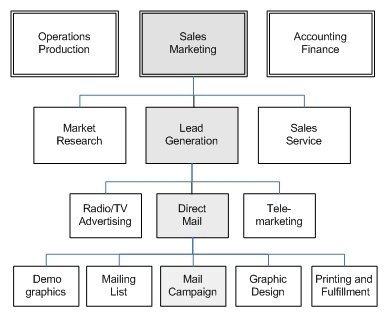

Solving problems is the central task of our business life; it is the profession you and I chose! Most of our problems arise from a business system or process that is under-performing—lead generation, customer service, employee training, order fulfillment, and so forth.

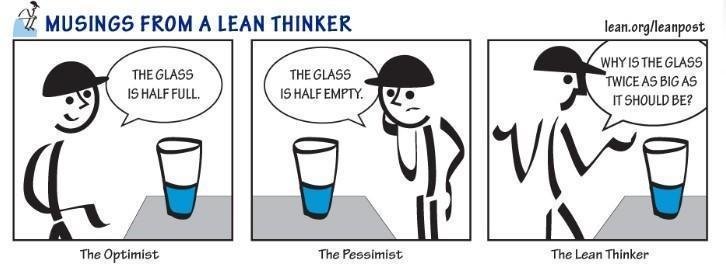

However, Systems Thinkers have an advantage by seeing the myriad of business problems through a logical lens rather than an emotional lens. By focusing on cause-and-effect, problems are more transparent and solutions more evident. Systems Thinkers resolve problems and make decisions systematically.

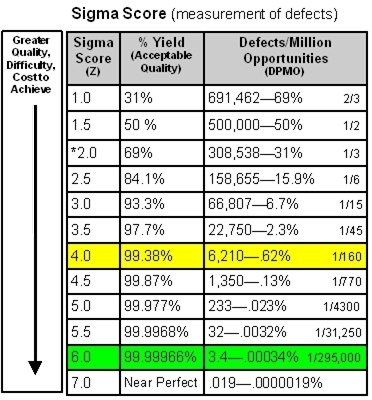

W. Edward Deming, leader of the quality revolution of the 20th century, said that 99 problems out of 100 are caused by the system. Fix the system and prevent reoccurring problems. It’s that simple. (see Jay Arthur, email newsletter, 2/2010).

Most small-business owners and managers tend to be satisfied with short-term solutions and workarounds rather than finding ways to solve problems permanently. The workarounds sadly become the standard way of doing business.

Four Easy Steps

Got a problem? Solve it once and for all by following the steps of a Systems Thinker.

- Identify problems from personal frustration, customer or employee feedback, or performance data. A clear statement of the problem often points to its own solution. Avoid dwelling on the past, and blaming people or a lack of time or money. Instead, concentrate on resourceful new ways to improve results.

- Go observe the system or process first-hand and talk with people to understand what is happening. Use a 5-Whys Analysis to drill-down to the specific step in the process that is the root cause of the problem. (Hint: This analysis might uncover the source of the problem in a different but related business system)

- Involve the team in a discussion or improvement meeting to identify possible solutions and get consensus and buy-in. Assign clear responsibility for implementing the solution. Set a deadline for completion and review. Help workers understand how changes in the business system will benefit them.

- After the new system has stabilized, compare actual with expected results. Provide frequent feedback to workers about how the system or process is performing. Celebrate success. If results aren’t acceptable, repeat the steps.

Learn from the Best

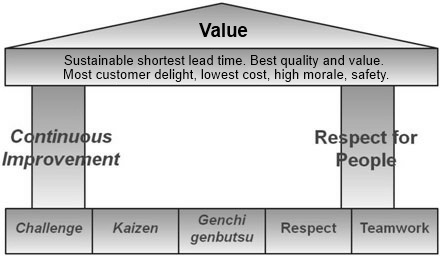

Toyota Motor Company, the father of Lean Manufacturing, does the following if there is a quality problem on a car assembly line:

“Stop production, go see what is going on, ask Why-Why-Why-Why-Why to find the root cause, implement an appropriate countermeasure (not a workaround) to permanently fix the problem, verify the solution works (if not, repeat the 5-Whys Analysis), resume production, and finally, add the solution to the company’s body of knowledge” (Jay Arthur).

Problem-solving doesn’t have to be difficult if you use a systematic approach. Discovering inventive ways to mistake-proof your business systems and processes can be very rewarding. Dramatic financial benefits are possible!

What problem is really frustrating you or holding back your company? Follow the steps above and let me know about your innovative solution.

Related Article

Try the “5-Whys” Problem Solving Tool