Every small-business owner should be acquainted with the profound yet simple principles contained in the Theory of Constraints.

This business improvement methodology is based on the premise that: “Every real system, such as a business, must have within it at least one constraint [limitation or restriction]. If this were not the case then the system could produce unlimited amounts of whatever it was striving for, profit in the case of a business. . .” (Dr. Eli Goldratt, “The Goal”).

In other words, every business or system has something preventing it from reaching its full potential—a weakness that limits its performance and output. This weakest point or constraint determines the maximum capacity of the entire system.

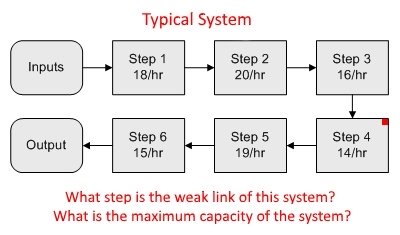

The flowchart below illustrates an example of a basic business process with six steps. It could be found in a production process, an office routine, or in providing a service.

You can see above that Step 4 is the slowest step, limiting the capacity of the system to 14 units per hour. It is also a bottleneck where work piles up from the steps preceding it.

Bottlenecks in business systems and processes are among the most damaging physical constraints and a barrier to achieving maximum results.

A bottleneck is any step whose capacity is equal to or less than the demand placed upon it; it can’t keep up with the inputs. A non-bottleneck is any step whose capacity is greater than the demand placed upon it.

You can only improve the results or throughput of a process by elevating the performance of the weakest step—the bottleneck. Improving other steps will not increase the system output.

Constraints are Everywhere

The Theory of Constraints applies to both service-based and product-based companies—in the office, the store, or on the production line. A constraint or weak link might include low customer demand, slow sales-lead follow-up, limited equipment or manufacturing capacity, order fulfillment bottlenecks, and so forth. Constraints are also the consequence of poorly designed business systems, untrained or an insufficient number of workers, adverse company policies, and even managers that are not Systems Thinkers.

A few years ago, I was the smallest investor in the smallest oil refinery in the country. Constraints in pump capacity, pipe diameter, and other physical components limited production to 3500 barrels of finished product per day. By upgrading the physical limitations—a significant cost—the capacity of the plant could have been much greater. However, it was even a challenge for the refinery to sustain its maximum throughput because of other constraints that frequently arose. For example, the plant had to slow and sometimes shut down when insufficient sales caused storage tanks to fill to capacity, or when empty railroad cars didn’t show up on time. Being without a backup generator was a constraint when severe weather caused power outages. Constraints causing downtime in this operation typically reduced profit by hundreds of thousands of dollars per month—an ongoing disappointment to investors.

Your organization is also filled with constraints that limit throughput, AND POTENTIAL PROFIT!

Elevating Constraints

Physical constraints are usually easy to spot. Just ask your employees what bottlenecks are slowing things down, and they’ll give you an immediate response. However, bottlenecks are not always easy to resolve.

Here are the five focus-steps from the Theory of Constraints that will help you elevate a constraint and improve the throughput of a system, and your entire business.

- Identify the constraints of the system. Look for work-in-process such as inventory or in-baskets accumulating in front of a task. That task is a bottleneck. Piled up work-in-process represents the inefficiency or waste of that constraint.

- Maximize the efficiency of the constraint. Utilize people, equipment, and schedules so that the constraint is working at 100% of its capacity. For example, add a night shift, work during lunch or Saturdays, change a schedule, or improve operator skills—whatever it takes to get the maximum use of the system constraint.

- Subordinate everything else to the constraint. Pace all other related tasks and processes to the capacity of the constraint—the weakest step. Do not let preceding processes over-produce causing a build-up of work-in-process.

- Elevate the constraint. Make the task a non-constraint by reducing the load or demand on it. The constraint is the most expensive step in a system or process because it restricts the throughput of the entire system. Ensure that the constraint is creating output committed for use or sale today, and not for inventory. Inspect items approaching the constraint to ensure only good-quality inputs are utilizing its limited capacity. Find alternatives to reduce demand on the constraint. For example, buy another piece of equipment or move some of the workload to another system. By doing these things, you elevate the task to a non-constraint.

- Look for a new constraint. When a task is elevated—no longer the weakest point of the system—look for the new constraint that has taken its place. Another task or step will now be the slowest part of the process. Thus, by always focusing efforts on the weak links and bottlenecks of your business, you get the maximum benefit from your improvement efforts. The most frequent constraint of many small businesses is insufficient sales. Product demand drives all other processes. Get your sales up and keep them as steady as possible!

Bear in mind that your objective is not just to eliminate the bottleneck of a particular process, but to elevate any system—in a sequence of systems—that constrains the throughput of the business as a whole

All your core business systems and processes must work in synchronization to achieve the highest efficiency and throughput. The more you reduce the barriers or constraints to your performance, the closer you come to realize your full potential.

Theory of Constraints: Performance = Full Potential minus Constraints

While efficiency and cost-cutting are important, the best measure of real business improvement is increased throughput—higher sales revenue and the resulting profit that comes from reaching your break-even point earlier in the month.

Now go find a bottleneck today, and ELIMINATE IT!

Related Articles

Six Sigma for Small Business—Improve Quality!

Lean Thinking for Small Business—Add Value!

Box Theory™ for Small Business–Create High-Performance Systems!

Feedback

Feedback