It is essential that someone in your company is responsible for sales. Somebody needs to do the accounting or bookkeeping. Someone oversees hiring, customer service, and order fulfillment. No matter what industry you are in, or the size company you have, YOU—or assigned employees—perform these and other basic business functions.

However, there is one essential job position that is rarely talked about and almost always ignored by entrepreneurs and small-business owners.

Laura’s Bad Experience

Consider this email—and cry for help—I received from a frustrated newsletter subscriber. Laura was the only person in her company to recognize this rarely thought about but important job responsibility. Could she be one of your employees?

Laura wrote:

“I can’t take it anymore! Chaos, pure unadulterated chaos. You could imagine myself (with the personality of a dragon) sitting down to convince owners we have to sort out all the tasks that people do into a logical workflow! So I created a Business Systems Department with the understanding they would know what it meant… uhmmmm no. I thought I was absolutely alone in the world until my assistant found your web site. Ahhhhh … there are people out there that actually think the way I do! I work for a company that is in denial. I want to work for a company that believes in having good systems.

“I am honestly tired of trying to convince this company that they should invest in their Business Systems, Best Practices, etc. If chaos is not enough to make them reconsider, if poor employee morale is not enough to make them reconsider… Well, you can quote me as a crazy lady who thought she could make a difference and become an asset to the company because I love this crazy world of Business Systems thinking… Anyhow, sorry for the long winded email but BOY that felt good to get it off my chest!” (This was about 25% of the actual email.)

The Invisible Job

Whether you have thought about it or not, your entire business operation is carried out with the help of systems and processes that come about formally or haphazardly through the years. These business systems are the way in which work gets done, and they are the building blocks of your organization. Their effectiveness determines your profitability and success.

Your systems and processes might include lead generation, sales conversion, production, order fulfillment, customer service, accounting, purchasing, hiring, and many others unique to your company.

So, what is a business system or process? Consider this down-to-earth definition:

A business system is a “recipe” for consistently getting a predetermined and desired result. The ingredients of a good business recipe may include materials, people, data, forms, checklists, tools, equipment, software, and so forth. The precisely followed step-by-step instructions, or procedure, ensure that the expected result is achieved every single time. Great recipes for getting routine work done in an efficient and effective way increase customer loyalty, employee performance, profitability, and growth.

So, who in your company is responsible for developing, monitoring, and maintaining the business processes that make your company run smoothly and profitably—even when you’re not around? Who in your company understands the underlying principles for creating effective systems and processes? Who in your company wears the hat of the “Process Improvement Manager”? Is it YOU, or someone else?

Wait, What? A Process Improvement Manager?

In a small business, the owner is the first “Systems Czar” (Philip Beyer) and usually begins documenting processes so that he or she fully understands how the business operates from start to finish.

Whether it is YOU, a manager or employee (full or part-time, and not necessarily a new hire), someone in your company needs to fill the essential role of a “Process Improvement Manager.” This person’s responsibility is to maintain efficiency and quality in the workplace. They evaluate current business practices, looking for ways to improve productivity and customer service, reduce costs, and make the best use of company resources.

Specifically, the process-improvement person develops, monitors, and elevates the performance of the company’s vital business systems and processes. Ongoing system development is the key to continuous learning, growth, and improvement of individuals and organizations.

A Process Improvement Manager is something of a “business engineer.” He or she is both logical and creative, able to identify and diagnose problems and find low-cost and innovative solutions. As you implement effective systems and processes, your company will stand out in a competitive marketplace, give customers a great buying experience, and improve operational quality and efficiency for a healthy profit margin.

So, What Exactly Does A Process Improvement Manager Do?

1. Develop and Reinforce “Best Practices”

While most people in a company see the business operation in terms of departments, functions, and activities, the Process Improvement Manager is focused on how efficiently and effectively the work is being completed. This person sees the details beneath the surface, where dollars are earned or lost, and operational success is determined. The Process Improvement Manager has a vested interest in:

Best practices

Cause and effect

Root-cause of problems

Performance standards and goals

Measured results and data

Employee motivation, training, teamwork, and incentives

Improvement and innovation

Getting the right people in jobs

Promoting growth and development of workers

Increasing the quality and efficiency of business processes

Eliminating bottlenecks, mistakes, delays and rework

Lowering costs

The Process Improvement Manager is always asking “WHY?” Why do we do this task at all? Why do we do it this way? Why are things not getting done on time? Why are there excessive mistakes or rework? Why are customers or employees unhappy? Why are we not reaching our goals?

“A relentless barrage of ‘why’s’ is the best way to pierce the clouded veil of thinking caused by the status quo. Use it often” (Shigeo Shingo, Toyota Lean Manufacturing).

The Process Improvement Manager seeks to find the best way to get the work of the organization accomplished with the highest quality and the lowest possible cost.

(“Management is doing things right; leadership is doing the right things” — Peter Drucker, renowned business consultant and author).

2. Apply the Master Skill

“If you can’t describe what you are doing as a process, you don’t know what you’re doing” (W. Edwards Deming, Total Quality Management).

All best-practices are arrived at by refining and improving daily operations, the company’s core business systems and processes. This is the primary focus of the Process Improvement Manager. His or her mandate is to create a smooth-running and profitable organization by taking the unwanted deviation, defects, and delay out of work processes. It is to ensure that customers are happy and desired results are consistently achieved.

W. Edwards Deming also said, “94% of all failure is a result of the system … not people. A manager of people needs to understand … that the performance of anyone is governed largely by the system that he works in, the responsibility of management” (Total Quality Management).

Effective business processes significantly reduce sub-standard performance, wasted resources, customer dissatisfaction, employee turnover, excessive costs, weak sales growth, inadequate cash flow, low profit margins, and daily frustration.

Your ability to create and refine the vital systems and processes of your organization is what I call the “Master Skill.” All business functions—marketing, finance, and operations—fall within the scope of this single skill mastery.

Most companies have one or two exceptional business systems that separate it from the competition. What innovative and remarkable business process makes your company stand out “like a purple cow in a field of brown cows”? (Seth Godin, Purple Cow)

(“No institution can possibly survive if it needs geniuses or supermen to [run] it. It must be organized in such a way [with effective systems and processes] as to be able to get along [with] average human beings” — Peter Drucker).

3. Recognize and Solve Problems

A two-word definition for “business” is “problem solving.” The Process Improvement Manager asks, “What problems do we need to address? What parts of our organization could improve? What obstacles do we need to overcome? What invisible termites are eating away at our customer loyalty or profit? Any core business activity that is falling short of its purpose or goals is a problem to be solved.

Business problems are usually observed up-close as mistakes, scrap or rework, delay or missed deadlines, excessive costs, and people having an unpleasant working or buying experience. Repetitive problems are made apparent by financial statements, performance reports, customer or worker feedback, and expressed complaints, frustration, or even opposing viewpoints.

Systems Thinking makes problems more transparent and solutions more obvious. A well-framed statement of the problem by the Process Improvement Manager will often provide immediate ideas for change. Data—the brutal facts—influence and direct all improvement efforts.

The Process Improvement Manager is always looking for the simplest and least-expensive way to solve a problem or improve a process—to take waste out of the business. Any problem-solving efforts may include prioritizing projects, budgeting for upfront costs (e.g., a new piece of equipment), and determining the ongoing operational costs of the new or improved system. It is often helpful to calculate the return on investment (ROI) by completing a cost-benefit analysis.

The Process Improvement Manager chooses the system-improvement projects that are the easiest to implement, or have the greatest financial impact, or that support company goals, or that will remove a weak-link, bottleneck, or frustration from business operations. They target a completion date and get buy-in, authorization, and financial support of decision makers before beginning a project. Focus plus prioritization equal fast results.

Care must also be taken when deploying any new system or process and training the people involved. Good preparation will reduce resistance to change. Workers who do not recognize the better way of doing things will produce a new set of problems.

(“If you want something good, you have to stop doing something bad” — Peter Drucker).

4. Encourage Learning and Growth in People

The best Process Improvement Managers are constantly learning, and they promote learning and growth in others. Whether by experience, mentors, books, performance reports, or feedback from customers or workers, they are always looking for clues, evidence, data, ideas, and strategies to get work done in a more efficient and effective way. They continually seek excellence in business operations.

Although change is constant, the Process Improvement Manager always has an eye fixed on the long-term mission and goals of the organization.

Knowledge is fleeting unless it is incorporated into behavior, into “best practices.” It is said that knowledge is power, but the real power to improve a business only comes when knowledge is applied to a specific system or process. The Process Improvement Manager tinkers with the procedure or the system components until the people and the process are getting acceptable results. Patience and persistence through obstacles and challenges yield a big payoff.

While workers do the “cooking and serving,” the Process Improvement Manager’s job is to step back, study, ponder, analyze, evaluate, plan, test, and keep improving the company’s unique and valuable business “recipes.”

(“The purpose of information is not knowledge. It is being able to take the right action” — Peter Drucker).

5. Hold Business Improvement Workshops

The Process Improvement Manager is on the move, working with others to elevate business operations. He or she does not try to solve every problem independently, but to become immersed in business processes, observe what is working and what is not, learn from those who have hands-on knowledge, and consider what improvements would yield better results.

The best way to benefit from the collective wisdom and experience of those involved in day-to-day operations is to “work ON the business” (Michael Gerber, “E-Myth”) in a weekly business improvement workshop.

During this one-hour meeting, the Process Improvement Manager, team leader, or other manager guides a discussion on specific business activities, systems, processes, or policies that need improvement. They whiteboard the process and consider each step along with the components or “ingredients” required for its success (e.g., materials, tools, checklists, etc.).

Those attending the workshop counsel together to achieve consensus on best solutions and practices. The leader reinforces the vision, strategy and goals of the organization, and gets buy-in and support for doing things in a new and better way.

Keep in mind that deployment of a changed system or process requires careful orchestration of people, resources, and timing. It is important to get a new system off to a good start.

Every little improvement uncovered in a business improvement workshop will serve to transform your company into a smooth-running, customer-pleasing, money-making business system! One-hour a week is all it takes!

(“Most discussions or decision making assume that only senior executives make decisions or that only senior executives’ decisions matter. This is a dangerous mistake” — Peter Drucker).

6. Document “the Way We Do Things Here”

I repeat W. Edwards Deming: “If you can’t describe what you are doing as a process, you don’t know what you are doing.” To which Michael Gerber adds: “If it’s not in writing, it’s not a system!” (“E-Myth Revisited”).

The Process Improvement Manager oversees the documentation of core business systems and processes and keeps them updated when changes and innovation occur. His or her job is to understand and describe in writing the best way to accomplish the routine work of the organization. However, documentation must be better than just a dust-gathering operations manual.

Preparing written systems and processes is the proper way to establish desirable work patterns and habits. These detailed “recipes” are of value to train new employees, and as ongoing references for experienced workers. They describe the required system components (ingredients) and the best procedure to follow.

This important “how-to” information remains constant, not haphazardly passed along by word-of-mouth or changed as people come and go from the job.

When processes are written and accessible to workers, less supervision is required. If a business is replicated or sold, documented business operations are of immense worth to those starting new.

(“Unless commitment is made [in writing], there are only promises and hopes… but no [action] plans” — (Peter Drucker).

7. Get the Right People, Leaders, and Teams

The Process Improvement Manager is not the Human-Resource Manager. However, he or she recognizes that people are the most important (and expensive) component of most business operations.

Therefore, the Process Improvement Manager is concerned with 1) how jobs are defined (job descriptions), 2) company policies that affect workers, 3) fitting the right person to the job, 4) making sure people understand their responsibilities and are properly trained, 5) establishing team leaders and teamwork for increased productivity, 6) meeting performance standards and goals, and 7) promoting accountability and work incentives. All of these items affect performance—the quality, efficiency, and cost of doing business.

Though often unnoticed, workers possess a variety of experience, talent, insights, and creative ideas that are just waiting for the right opportunity to be shared. A good Process Improvement Manager cultivates relationships and is always listening for useful suggestions and bold ideas to improve business processes. They love to give credit, recognize contributions and exceptional achievement, and celebrate success. Getting thought-leaders and exemplary workers behind a new idea will encourage others to follow.

Continuous and unrelenting effort to improve systems and processes is the only way to develop excellence in people and organizations.

“Reward those who Do, Train those who Can’t, Replace those who Won’t” (Henn’s Creed). The Process Improvement Manager is interested in two major factors that affect how workers perform—Desire and Capability. They find ways to elevate both.

(“Only three things happen naturally in organizations: friction, confusion, and under-performance. Everything else requires leadership. … The key [is] to … look for people’s potential and spend time developing it” — Peter Drucker).

8. Speak Numbers, the Language of Improvement

“Without data, you’re just another person with an opinion” (W. Edwards Deming).

The Process Improvement Manager relies heavily on data or numbers in their pursuit of truth and best practices. Their personal success is largely determined by the company’s ability to show measurable improvement of its core business activities. Numbers are the language of improvement.

However, the daily work of the Process Improvement Manager is not just to focus on outcomes, but instead to improve the behaviors and processes that lead to better outcomes or numbers.

Many operational problems are revealed in performance reports or financial statements such as the balance sheet or the profit and loss statement. These numerical indicators will point to weak or faulty business processes.

The Process Improvement Manager is interested in common business measures, including performance standards and goals, break-even points, and the key numbers that drive the success of the organization. Knowing the sometimes-dreadful facts is essential to making effective changes.

Workers also excel when they receive frequent performance feedback, and by always knowing where they stand in relation to established goals or standards. Properly viewed, numbers provide the critical foundation for all business intelligence.

“You cannot manage what you cannot measure” (Peter Drucker). “Anything that can be measured can be improved” (Michael Dell, Dell Computers). When performance is measured and reported, the rate of improvement accelerates” (Thomas S. Monson, business and religious leader).

The time and effort of the Process Improvement Manager is a financial investment that must have a beneficial return. This is accomplished by focusing on the systems and processes that improve the customer experience and reduce costs (waste). The larger the company, the greater the opportunity there is for financial gains.

Before beginning any improvement project, the Process Improvement Manager determines the initial cost of implementation as well as the annual recurring costs. A preliminary analysis may include a budget, expected savings or earnings, and the estimated payback period.

Owners or managers approve new projects before proceeding and receive regular status updates, especially the good news of financial gains. Well-designed and executed business systems pay for themselves many times over.

(“Leadership is defined by results not attributes. … Checking the results of a decision against its expectations shows executives what their strengths are, where they need to improve, and where they lack knowledge or information” — Peter Drucker).

9. Never Stop Improving and Innovating

Kaizen, a Japanese term for continuous improvement, is the ongoing, systematic, incremental improvement in the way things are done. It is a relentless attempt to eliminate unnecessary business activities, delay, waste, and variation within processes that add cost without adding value. Kaizen results in improved lead-time, efficiency, quality, productivity, and customer loyalty.

Every organization has unlimited possibilities for improvements that lead to happier customers and higher profits. The Process Improvement Manager is focused on bettering people, products, and processes, turning problems into opportunities, and achieving operational excellence in a never-ending quest for perfection.

Most improvements in an organization come from ongoing innovation to its internal systems and processes (e.g., reducing errors or cycle time). Some improvements are incremental—tweaking what already works. However, breakthrough improvements can dramatically elevate the customer or worker experience and reduce operational costs in a BIG WAY.

“The goals of a Process Improvement Manager are simple: 1) make things easier 2) better 3) faster and 4) cheaper” (Shigeo Shingo, pioneer of Lean Thinking). They continually ask, “How can we do this better? How can we raise the standard?”

Daily improvement is accomplished by measuring and monitoring core business activities and providing constant feedback to workers and managers. Suggestion boxes, done the right way, and business improvement workshops (discussed above), are also sources for new ideas and input from workers.

Improvement methodologies such as Six Sigma, Lean Thinking, and the Theory of Constraints provide big-league principles and strategies for even the smallest of companies (see “Four Improvements Methods You Should Know About”). Small daily improvements—hundreds each year—are the key to extraordinary long-term results.

(“Knowledge has to be improved, challenged, and increased constantly, or it vanishes. … Not to innovate is the single largest reason for the decline of existing organizations” — Peter Drucker).

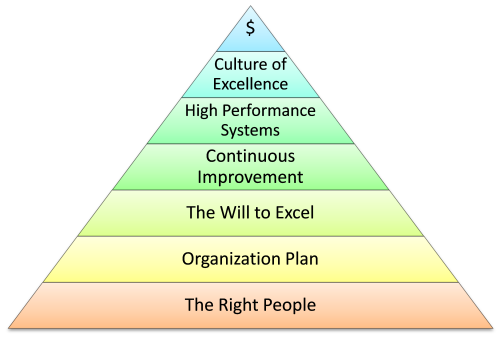

10. Inspire a Culture of Excellence

The Process Improvement Manager has a great influence on the culture of the business, and culture drives results more than any other factor.

“An organization’s purpose and goals set the direction. Measures focus the energy on the outcomes. Processes create habits, and habits drive the culture. You can teach skills and concepts. You can even create momentum (and a few smiles) through inspiration. But investing in skills and inspiration is a waste of money if there are not processes to reinforce your purpose and principles. The creation and continuous refinement of work processes is a mandatory practice in the Results Rule! organization, regardless of the industry” (Randy Pennington, “Results Rule!”).

The Process Improvement Manager—owner or employee—is responsible to help the company breakthrough to a high-performance culture, a culture of discipline, a culture of excellence. This is the natural consequence of creating effective business systems and processes. There is no other way!

(“Culture eats strategy for breakfast” — Peter Drucker).

Nate’s Amazing Experience

Ten years ago, a young man sat quietly in one of my workshops. He was an entry-level employee of an attending customer. Little did I know how much he was paying attention, and that he caught the vision far beyond the business owner he was working for. Years later, and unexpectedly, I received an email from Nate. In part, he wrote:

“I am now working for a fortune 1,000 company and am currently in the business intelligence sector, and I am a Business Process Engineer. I go in, evaluate, look for waste, streamline processes and identify projects. I am then tasked with implementation, setting up control reports, forecasting results, and mapping out potential financial gains. I have been in the job for four months now and things are going so well they are throwing all kinds of projects at me that span many departments. I gained trust quickly and pretty much have a free rein. I have already identified over $10 million in gains from process improvements that I am putting in place.”

Nate made a career of process improvement and landed a great job with a big company. However, the principles that guide his work are much the same for companies of every size. YOU CAN AND SHOULD DO THIS FOR YOUR COMPANY! As with Nate, the payoff can be quite substantial.

Laura (quoted above) and Nate, have had very different experiences in the companies they work for. All customers and employees, including yours, have similar feelings, one way or the other. Is your company organized, systemized, smooth-running, efficient, and profitable, or is it seat-of-the-pants, frustrating to do business with, and struggling to make money? Perhaps it is in between, but could it use some improvements?

Again, Who is Your “Business Systems Czar”?

The primary purpose of a Process Improvement Manager is to help engineer a remarkable business operation. This person has proven leadership and communication skills (oral and written), is a problem-solver with sound business understanding, works well with people and teams, and is performance-driven.

The Process Improvement Manager spends most of their day designing, developing, overseeing, monitoring, and evaluating the systems and processes that help an organization effectively find and keep customers, run an efficient and profitable operation, and differentiate itself in a crowded marketplace.

Workers run the systems, and systems run the business. People may come and go, but the systems and processes remain constant. (see Michael Gerber, “E-Myth Revisited”). Like a fine restaurant, the key to success is developing and executing the precise and proven “recipes.”

(Oh, and by the way, the Process Improvement Manager should also document the “recipe” for their own role and improvement activities.)

Why Should People Want to Do Business with You?

Customers and employees alike want to work for or do business with the best companies. In a competitive marketplace, expectations are rising.

“Customers … are demanding from companies in many industries a radical overhaul of business processes. Intuitive interfaces, around-the-clock availability, real-time fulfillment, personalized treatment, consistency [across locations], and zero errors—this is the world to which customers have become increasingly accustomed. It’s more than a superior user [or buying] experience, however; when companies get it right, they can also offer more competitive prices because of lower costs, better operational controls, and less risk.” (Shahar Markovitch and Paul Willmott, McKinsey & Company).

So, just like sales, accounting, and customer service—essential business functions—you also need someone to develop and refine the business processes that are humming along every day in your large or small organization.

Incremental and occasionally breakthrough improvements will dramatically increase your customer loyalty, employee performance, profitability, and growth. There is no other way!

(“The best way to predict the future is to create it” — Peter Drucker).

P.S. – Download and print this article for your reference or to give your designated Process Improvement Manager. Go through the article and highlight everything your company can and should do. (Owners of small businesses will be surprised by the possibilities.) These ten principles will get you off to a great start! (Click Here to Download Printable PDF File)